East West Industries provides full turnkey manufacturing services as a leading contract manufacturer in Asia. We offer the advantages of finding local competitive sources for all components whether raw material or semi-finished components. We have the advantage of utilizing an extensive supply-chain across Asia when localization is not possible in Vietnam.

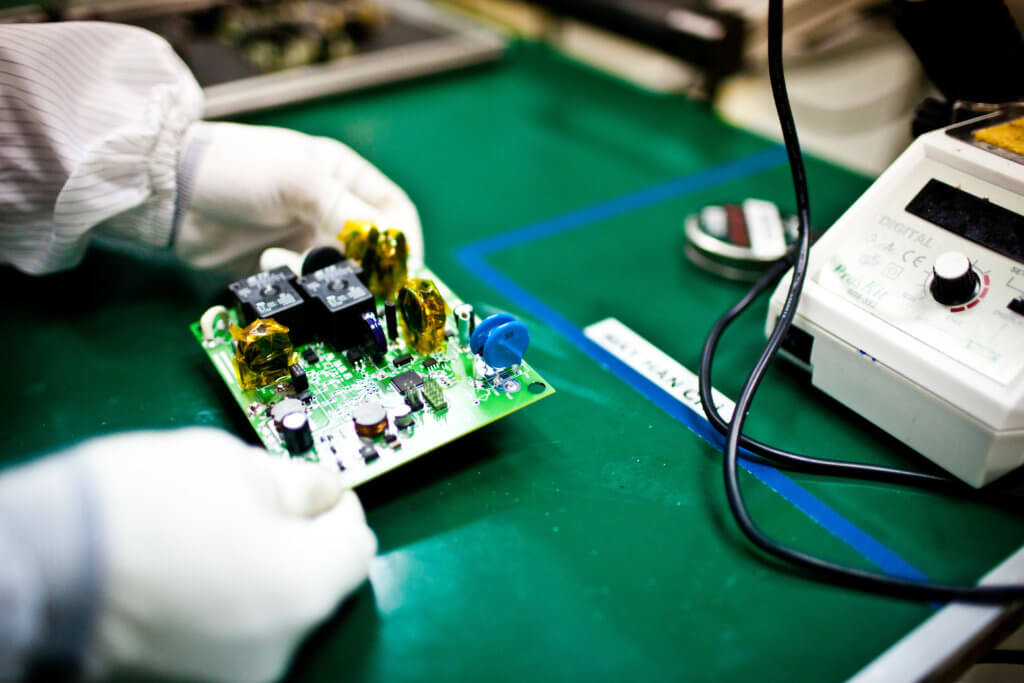

We build to your designs, according to your specifications. With in-house PCB assembly, injection molding, stamping, pad printing, and assembly, combined with our sourcing capabilities, we’re able to fulfill your manufacturing requirements whatever they may be.